The Ultimate Guide to Acrylic Laser Cutting: Techniques, Benefits, and Applications

Acrylic laser cutting has become a preferred method for achieving precise and intricate designs across various industries. Whether you’re in the signage, interior design, or display industry, laser cutting offers unmatched accuracy and efficiency. This guide explores the techniques, benefits, and applications of acrylic laser cutting to help you understand its potential.

Understanding Acrylic Laser Cutting

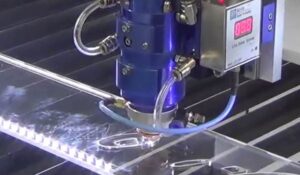

Acrylic laser cutting is a procedure that uses a high-powered laser to cut over acrylic sheets with precision. The laser beam melts, vaporizes, or burns the material, creating clean, smooth, and polished edges. Unlike traditional cutting methods, laser cutting eliminates the need for post-processing, making it a preferred choice for businesses requiring fine detailing.

Key Techniques Used in Acrylic Laser Cutting

- Vector Cutting – This involves cutting through the acrylic using a focused laser beam to create clean and sharp edges. It is ideal for making intricate shapes and patterns.

- Raster Engraving – Instead of cutting through the material, this technique engraves the surface of the acrylic, adding detailed designs, text, or logos.

- Polished Edge Cutting – Laser cutting naturally produces smooth, polished edges without additional finishing, making it ideal for high-end display products.

- Kiss Cutting – This technique creates partial cuts, allowing for bendable designs or layered structures in acrylic.

Benefits of Acrylic Laser Cutting

1.High Precision and Accuracy

Laser cutting technology ensures sharp, clean cuts with minimal material wastage. It allows for detailed and complex designs that are difficult to achieve with traditional cutting methods.

2.Smooth, Polished Edges

Unlike mechanical cutting, laser cutting produces smooth and glossy edges without additional finishing, enhancing the overall appearance of the product.

3.Speed and Efficiency

Laser cutters operate at high speeds, reducing production time and increasing efficiency. This makes it a cost-effective solution for bulk production.

4.Versatility

Acrylic laser cutting can be used for a variety of applications, including engraving, cutting, and etching. It is suitable for a wide range of industries, from advertising to interior decoration.

5.Minimal Material Waste

With precise cutting capabilities, laser cutting reduces material wastage, making it an eco-friendly choice for businesses.

Applications of Acrylic Laser Cutting

1.Signage and Displays

Acrylic laser cutting is widely used for creating high-quality signage and display products, such as illuminated signs, business logos, and promotional displays.

2.Interior Design and Decoration

From decorative wall panels to furniture components, acrylic laser cutting is popular in interior design for its aesthetic appeal and versatility.

3.Retail and Exhibition Displays

Retailers use acrylic laser-cut products for display cases, standees, and customized promotional materials to enhance their brand presence.

4.Industrial and Manufacturing Applications

Industries utilize laser-cut acrylic components in prototyping, machine parts, and automotive applications due to its precision and durability.

5.Personalized Gifts and Accessories

Acrylic laser cutting is ideal for creating custom-made gifts, awards, keychains, and jewelry with intricate designs and engraving.

In Conclusion

Acrylic laser cutting is a revolutionary technique that offers unmatched precision, efficiency, and versatility for various industries. Whether you need high-end display products, intricate signage, or decorative elements, this cutting-edge technology ensures superior results. For premium-quality acrylic display products crafted with precision laser cutting, Acrylic Gallery Display Products LLC is your trusted partner.