HOW TO BEND ACRYLIC SHEETS

HOW TO BEND ACRYLIC SHEETS

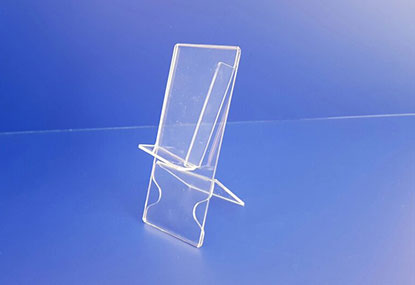

Bending acrylic is accomplished by heating the sheet, which causes the heated portion to become thermoformable, allowing it to be bent into place. Acrylic softens and bends easily when heated to 160 degrees Celsius. It’s best to continue with caution. To avoid damaging the material on the outside of the fold, bend the acrylic slowly and softly. Heat the acrylic on the outside of the fold line briefly after bending it to seal it correctly.

Acrylic is ideal for a variety of products since it is flexible and can be moulded into any shape. They are perfect for use outdoors because they can withstand temperatures of up to 160 degrees Celsius. Acrylic crockery and glassware are popular in restaurants because they are durable, shatterproof, and easy to clean.

Bending Acrylic With Heat Gun

Step 1:

Gather the materials you’ll need to use a heat gun to bend the acrylic.

- acrylic sheet (big enough for your needs)

- A heat gun is an electronic equipment that warms and softens a wide range of materials.

- Recycled wood

- Dremel saw, circular saw, table saw, and/or razor knife

- clamps and a vise

- Chinagraph pencil, also known as a grease pencil, or permanent marker

- Acrylic glue and an applicator

Step 2:

Decide on the measurements of what you’re going to make with the bent acrylic. If you’re making an enclosure, you’ll need to do some arithmetic to figure out how big it should be and where you should bend it to get the shape you want.

- You may need tools such as a ruler or other measuring stick, a square, a compass, or a protractor to find these dimensions.

- Once you have calculated your dimensions, mark them up on the acrylic so that you know where to cut. A China graph pencil or permanent marker works well, but the marker will not be able to be removed.

- If you want any holes in your acrylic enclosure, it is better to drill or cut them into it before bending, as this process is easier while the acrylic is still flat.

Step 3:

Place the acrylic between two scrap pieces of wood, one of which is your jig, and use the vise to clamp it all together. If necessary, cut the jig to assist you in bending the acrylic to the correct calculations.

- If you’re cutting a jig, this is where you can utilise the circular or table saw. A jig is a box or frame that is used to hold a material and guide a machine tool to it. Based on your calculations, the jig will be cut at a specific height and with a specific angle on its edge so that you may bend the acrylic correctly.

- Make sure you have a scrap piece of wood on hand to assist you with the heat bending. You’ll use it to press down on the heated acrylic.

Step 4:

Prepare your heat gun for bending the acrylic. Heating is a slow process in order to make sure that you get a straight bend in the acrylic

- While aiming the heat gun at the acrylic, use the spare piece of flat scrap wood to push it back and forth. While pushing, keep your pressure on the acrylic as even as possible.

- While pushing back and forth on the acrylic, slowly move the heat gun side to side.

- It’s important to keep in mind that the acrylic will most likely bend gently at first. Take your time and be gentle, gently bending the acrylic to avoid cracking it.

- If the acrylic is thin enough, you might be able to use a blow dryer instead of a heat gun if you don’t have one.

Step 5:

Repeat the heating process if you have additional bends to make in the sheet of acrylic. This will be necessary if you are making an enclosure out of the acrylic, for example, but it will not be necessary in every situation. If you have no further bends to make, then move on to the next step, or you may be done with your project at this time.

- It will be helpful to allow each bend to completely cool before going on to the next bend so that you do not lose the initial bend.

Step 6:

To build the side pieces, trace the sides of your freshly bent acrylic piece. Trace the sides of the bent acrylic with a permanent marker or Chinagraph pencil on a new piece of flat acrylic. When you’re finished tracing, use a Dremel saw or a razor knife to cut away the side pieces.

- Each side of the bent acrylic should be traced. Don’t make the mistake of assuming that all sides have the same shape.

Step 7:

Set the bent acrylic piece and the cut sides together with acrylic glue and the applicator. This can be a tricky process.

- Be very careful while bending the acrylic and cutting your side pieces, as the acrylic glue requires perfect seams in order set correctly.

- The acrylic glue requires at least five minutes to set, so it is recommended to clamp the enclosure together to help it set correctly.