ACRYLIC LASER CUTTING

The digital subtractive production technique known as acrylic laser cutting entails utilising a laser to cut or engrave a particular material. The manufacturing industry generally uses laser cutting to create shapes or designs in sheetmetal or other structural materials, but other sectors, like schools and hobbyists, are also starting to use it more frequently. Our acrylic based products like acrylic cake topper, led sign board, etc. Extruded acrylic is the best for laser cutting because it forms a flame polished edge during the acrylic laser cutting process.

Applicable Laser Processes for Acrylic :

- Laser Cutting

- Laser Marking

- Laser Engraving

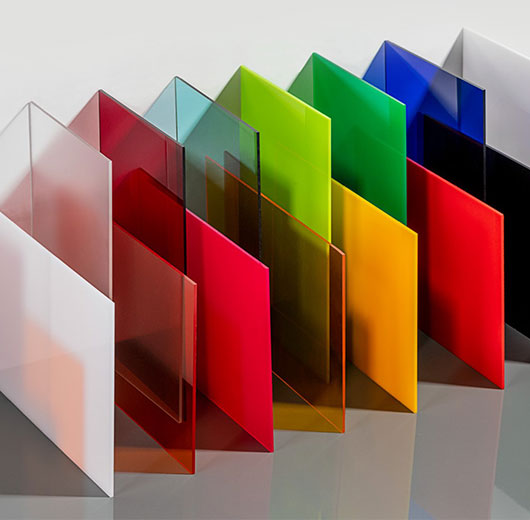

Types Of Acrylic

Cast Acrylic:

Cast acrylic sheets are created by pouring liquid acrylic into moulds that can be configured into a variety of shapes and sizes. The majority of the trophies you see on the market are made of this particular sort of acrylic. Because cast acrylic develops a frosty white tone when engraved, it is the perfect material for engraving. Cast acrylic can be laser cut, but the edges won’t be flame-polished.

Engraving works better on this acrylic medium.

Extruded Acrylic:

Extruded acrylic Sheet, which is the second type of acrylic, is a highly common cutting medium. Extruded acrylic is created using a higher volume manufacturing process, which makes it less expensive than cast acrylic and causes it to respond to the laser beam very differently. When laser cut, extruded acrylic will provide a smooth, crisp cut with a flame-polished edge. However, when it is etched, you will see a clear engraving rather than a frosted appearance.

Method of Acrylic Laser cutting

There are a number of techniques that you can always use for acrylic laser cutting.

Acrylic Laser Cut Design:

These describe the specific laser cut designs that you would want to have made from the acrylic material. The designs can be created in whatever shape you like and vary depending on a wide range of factors. Most of the time, it’s the designs that make it possible for you to get a laser cut from a whole laser sheet or piece of material.

Reactive Cutting Acrylic Sheet:

It is also frequently referred to as burning stabilised laser gas cutting or flame cutting. This method is similar to cutting with an oxygen torch, except it ignites with a laser beam. This technique is typically useful for cutting materials that are thicker than 1 mm. By using less laser power, you may also use this technique to cut relatively thick acrylic sheets.

Melt and Blow Acrylic Sheet:

This technique is often referred to as fusion cutting. The primary method it employs to remove molten material from the area you’re cutting is high-pressure gas. This is crucial since it significantly lowers the amount of power needed. The substance is initially heated till it reaches the melting point. In order to avoid the need to raise the material’s temperature, there is then a gas jet that blows molten material out of the kerf. It is an effective way of cutting acrylic and yielding a top quality result.

Acrylic Sheet Cutting Vaporization:

This style of cutting creates a keyhole by heating the acrylic material’s surface to the point of boiling. This keyhole causes an abrupt rise in absorptivity, which causes the hole to quickly deepen. It produces vapour as the hole continues to get deeper and the substance inside boils. The vapour’s pressure causes the ejecta to be blown out and the walls of the molten substance to dissolve, thereby widening the keyhole. It is also regarded as one of the best methods for cutting acrylic material.